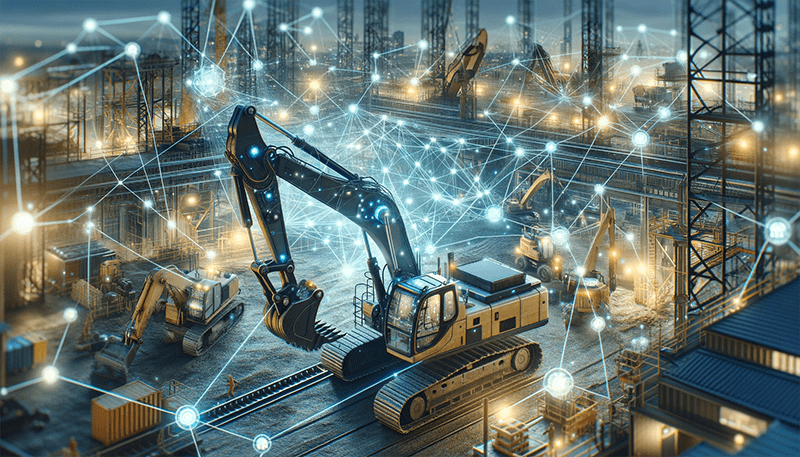

The landscape of Machine-to-Machine (M2M) communication is evolving rapidly, proving to be a pivotal element in sectors like construction, mining, agriculture, and others. Today’s progress is more than just new machines and equipment. It is about bringing in robotics and autonomous systems that need stable and reliable connections. Not every network technology is up to the task – the connectivity required for them to work flawlessly should be extra reliable, flexible and mobile.

In this blog, discover Meshmerize’s innovative approach to industrial networking. Join us as we explore how Meshmerize addresses industrial connectivity challenges, significantly changing the dynamics of M2M communication.

The rise of robotics and their growing role in the industries

Despite the still-growing presence of robots in construction sites and agriculture fields, the clear need for robust connectivity highlights their immense potential and the promising future of these technologies. Some sites use autonomous trucks and advanced machines like Boston Dynamics Spot robots. This gradual integration marks a significant shift towards enhanced efficiency and safety.

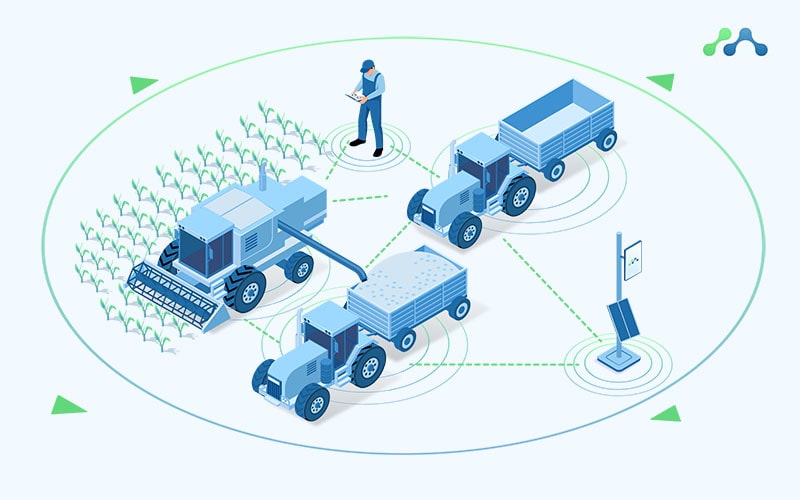

The global construction robot market, as per Next Move Strategy Consulting, is expected to grow from $85.3 million in 2021 to $242.4 million by 2030. Agriculture is also witnessing a steep rise in robotic technology. The agricultural robotics market, according to Fact.MR, could surge from $5 billion in 2022 to $30 billion by 2032.

Alongside the advanced machines, regular vehicles and equipment also require reliable connectivity. This highlights the growing demand for sophisticated network solutions that could cater to their dynamic needs.

Understanding the dynamic needs of M2M communication

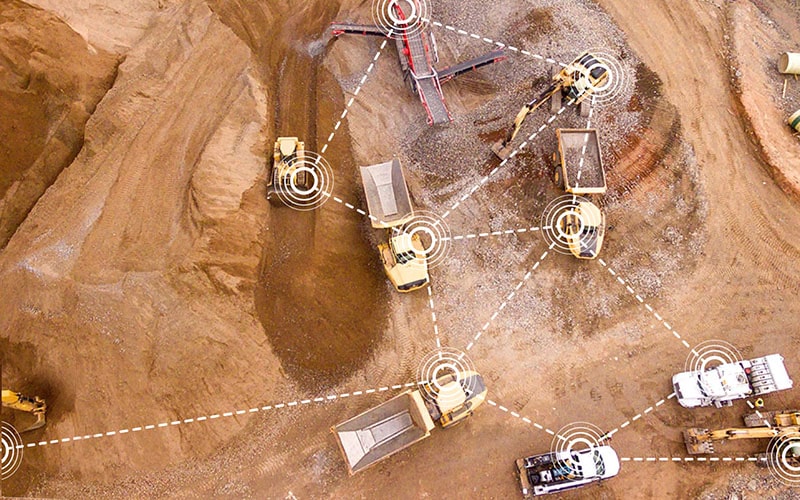

These dynamic and often remote environments pose unique connectivity challenges. Consider a highway construction site miles away from the city, where cellular networks are weak or nonexistent. Similarly, agricultural fields and mining sites, often expanding in size, require a network that grows and adapts with them.

Such locations are riddled with signal blind spots, created by towering dirt piles, underground tunnels, and large metallic structures, not to mention the heavy machinery itself. Each of these factors disrupts connectivity, creating operational hurdles. For example, when a machine loses its connection, work stops, and someone must intervene to restore connectivity, leading to productivity losses.

Furthermore, these environments demand a flexible network. Machines with different functions constantly move in and out of these sites, necessitating a network that allows for simple, seamless entry and exit. The adaptability of the network is crucial, as it must accommodate the changing landscape and machinery needs without compromising efficiency or safety.

Why traditional connectivity solutions fall short in dynamic environments

Knowing the challenges, traditional connectivity solutions like Wi-Fi, LTE, and 5G face limitations in industrial environments. Wi-Fi struggles with range and interference, making it unreliable in areas rich with obstacles. LTE, while offering broader coverage, cannot adapt quickly to the constantly changing landscapes of sites like mines and construction areas. And while 5G promises enhanced speeds and lower latency, its deployment is costly, especially in remote areas, and it still struggles with underground penetration and blind spots. These challenges underscore the need for more specialized solutions to meet the unique demands.

What makes machines click seamlessly with Meshmerize?

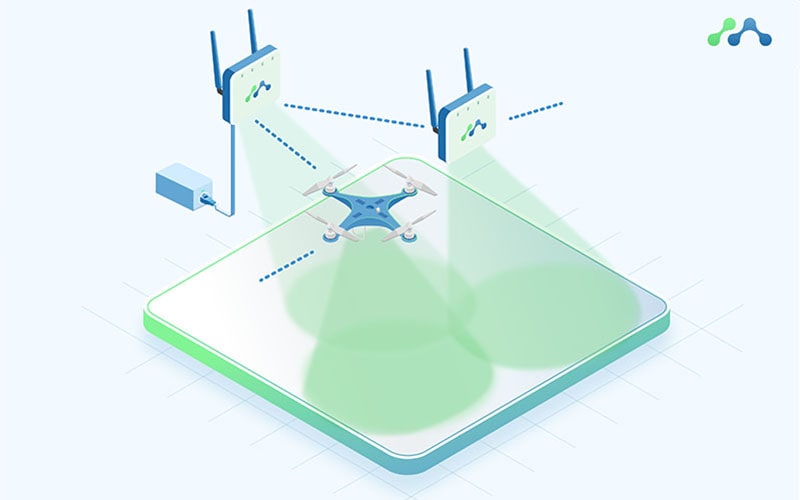

Meshmerize stands out with features tailored for last mile M2M communication. Its strengths include seamless roaming, rapid reconnection times, and range extension through other devices.

Blind spots? No problem. As long as there is a line of sight between two devices, Meshmerize ensures that the connection remains stable and consistently operational, even if it is established indirectly through other devices or machinery.

Imagine a vehicle seamlessly entering and exiting the network without any manual setup – also a reality with Meshmerize. The mesh excels in seamless roaming and rapid reconnection, essential in constantly evolving sites.

A construction site typically expands and changes over time and the Meshmerize network grows and adapts effortlessly with it. The network extends its range through other devices, ensuring that no area, no matter how remote, is left disconnected. In scenarios like platooning or remote operations, where precision and timely response are vital, Meshmerize multi-path routing, near-zero handover time, and prioritizing traffic prove invaluable.

One of the key aspects of Meshmerize is its hardware independence. Our mesh network software can be integrated into a wide range of out-of-the-box industrial access points, offering unparalleled flexibility. This adaptability extends to existing infrastructure as well, allowing for cost-effective retrofitting.

Additionally, Hive, our innovative Meshmerize network management tool, enables static and mobile node visualization, simplifies the process of adding or removing nodes, and makes sending timely alerts and notifications simple. This powerful tool ensures efficient and straightforward network management and monitoring.

Proven Successes

We are proud of our contributions to advancing connectivity in various industries.

For instance, during the DARPA challenge, we successfully connected APs and Spot robots, showcasing our system’s proficiency in complex underground environments. In the 5G Fola project, we established a secondary mesh network, offering a needed resilient backup to the existing cellular network. Additionally, our tests with harvesting machinery in agricultural fields have been triumphant, demonstrating Meshmerize’s ability to enhance operational efficiency in many ways.

These successes demonstrate Meshmerize’s capabilities and fuel our excitement to showcase even more of what our technology can achieve in the future.

The Reliable Future of Industrial M2M Connectivity

In industries like construction, mining, and agriculture, connectivity challenges are numerous. As these industries gradually embrace more advanced machinery and robotics, the need for robust, adaptable connectivity becomes crucial.

Meshmerize, with its innovative approach, is poised to meet these evolving demands. With instant reconnection, zero-setup network, near-zero handover time, and prioritized routing, our mesh network software solution is redefining the standards of industrial M2M networks.

Meshmerize is a startup based in Dresden, Germany that provides the ultimate mesh network software to an array of industries. The full potential of Meshmerize is yet to be seen. We would like to hear your thoughts – let us know what you think at hello@meshmerize.net