Automation is gradually finding its place, from manufacturing, intralogistics, and agriculture to drone technology, construction, and mining. As autonomous vehicles and robots grow in numbers, their potential to enhance efficiency and safety becomes increasingly evident. This is the road of industrial connectivity and technology in 2024, a landscape marked by innovation, automation, and the relentless pursuit of efficiency. At the heart of this transformation lies the undeniable truth: autonomous systems drive the change, and perfect connectivity is the key to their success.

As we explore these exciting developments, we will also confront challenges that demand substantial attention. Safety concerns, talent shortage, and the need for industry-appropriate network technology are all pivotal aspects of this evolving industrial landscape.

1. Safety: the automation buzzword in 2024

The rapid rise of autonomous systems in 2024, especially in public spaces, has ignited a palpable concern among the general public. It’s perfectly understandable. To shed light on these concerns, let’s explore a few scenarios.

In agriculture and similar industries, autonomous machinery must stop if they deviate slightly from their path, posing challenges in remote areas with unreliable networks, leading to productivity losses. Additionally, regulations prevent these machines from using regular roads, requiring additional transport methods.

In logistics, AGVs usually navigate using preloaded maps. Connectivity loss can lead to disoriented AGVs entering restricted areas, posing accident risks.

For drones, losing stable connection can lead to emergency landings in hazardous or inaccessible places like treetops, dense forests, rooftops, or busy streets, creating risks for recovery and potential damage.

Autonomous machines require absolute reliability, particularly where immediate manual intervention isn’t possible. Robust and reliable connectivity is essential, not just convenient.

2. Lack of talent driving the adoption of autonomous systems

The industrial world is in the midst of a talent crisis. Industries such as agriculture, construction, and intralogistics, are struggling to find the skilled workforce they require. As the presence of autonomous systems grows, the talent gap widens. The two are causally connected, and the need for human and automated workers is rising at an equal pace.

In this pursuit, safety and efficiency are paramount. We know the required human worker conditions, but what drives the productivity of autonomous systems? Among other things, they demand perfectly reliable connectivity.

3. Affordable industrial connectivity and the pressure for lower prices

The transition of autonomous technologies, like driverless trucks and drones, from military to civilian use brings a crucial challenge: affordability. These innovations originate in high-cost defense projects and now face the pressing need for cost-effective adaptation for public use, with connectivity as a vital functionality aspect.

This shift demands reduced prices but also maintenance of the promised performance. The focus extends beyond mere cost-cutting. It’s about making these advanced technologies and their integral connectivity solutions accessible to a broader audience.

While 5G is often heralded as a solution, its high installation costs and some typical industrial connectivity challenges highlight the need for more practical, industry-specific connectivity options. The goal is to democratize these autonomous systems, ensuring they are affordable and efficient for diverse civilian applications, thus fostering inclusive access and innovation.

The non-negotiable need for reliable industrial connectivity

For autonomous systems to function seamlessly, perfect connectivity is non-negotiable. Phones or public services can tolerate occasional offline moments, but machines cannot.

Traditional networks like Wi-Fi, while still being the workhorse of the industries, often grapple with industrial challenges such as signal blind spots and roaming issues in both indoor and outdoor settings. Even 5G, with its promise of future-ready connectivity, isn’t immune to these limitations.

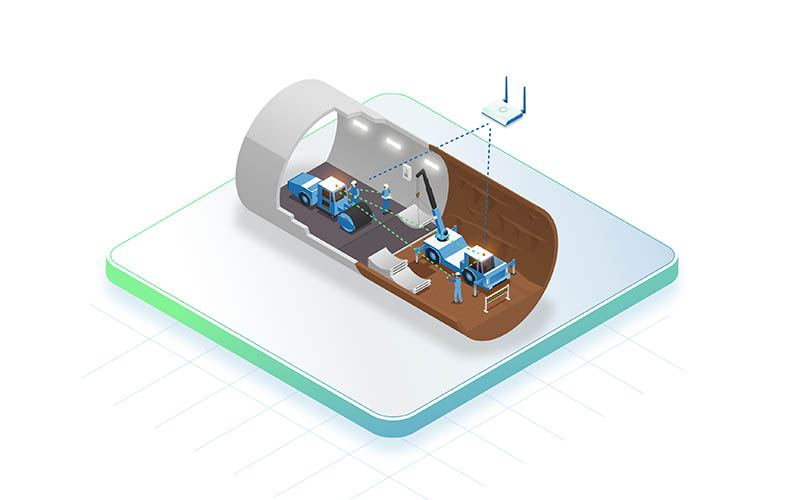

In this landscape Meshmerize reliably complements existing technologies like 5G and satellite links. Our approach provides flexible and dependable wireless connectivity, specifically tailored to overcome the unique connectivity hurdles in industrial environments.

Meshmerize is dedicated to enhancing connectivity across various fields. Our solution addresses the specific needs of sectors like agriculture, construction, drones, and mining, offering seamless integration and robust performance tailored to fit the demands in 2024 and for many years to come.

6G: “The network of all networks”

6G embraces the principle of ‘one size does not fit all’, enabling the selection of the most appropriate solution for each unique use case, be it Wi-Fi, mesh networks, or other connectivity options. It operates on the premise that different connectivity needs require tailored solutions. It envisions facilitating local networks that seamlessly connect to a larger network, often the cellular network. We heard it being called the “network of all networks.” 6G is poised to evolve and play an increasingly pivotal role in 2024 and the following years.

100% connected autonomous systems in 2024 and beyond

The automation direction for 2024 is clear. Autonomous systems are revolutionizing industrial operations, demanding unwavering reliability.

Addressing key challenges such as talent shortages, safety concerns, affordability, and the need for advanced network technologies is imperative to fully leverage automation capabilities. These remain the foremost issues in 2024’s industrial landscape.

The evolution of 6G technology, with its adaptable and inclusive connectivity solutions, promises to enhance industrial operations. Meshmerize, with its mesh network software solution, is perfectly aligned with this changing industrial environment.

As we look to the future, the prospects for flawless industrial connectivity are promising. We at Meshmerize are thrilled to contribute to this dynamic journey, playing a role in shaping the future of industrial connectivity.

Meshmerize is a startup based in Dresden, Germany that provides the ultimate mesh network software to an array of industries. The full potential of Meshmerize is yet to be seen. We would like to hear your thoughts – let us know what you think at hello@meshmerize.net