Without a doubt: automated guided vehicle or AGVs are helping to revolutionize the automated warehouse. These robots are designed to work alongside humans in picking and packing operations. What makes them amazing is that AGVs are increasing efficiency and accuracy while reducing costs and injuries. AGVs made a huge shift in how a warehouse operates. This also brought certain issues that require special attention, and that means time and money. When an industrial robot loses connectivity for some reason, e.g. loses connection to the Wifi router, it takes some time for it to re-establish the connection. In some situations, the whole work process has to stop to stabilize the AGV network. The longer the system is out, the more money is lost. But there are ways to circumvent this problem and deploy a reliable AGV network.

First of all, let’s talk about the automated warehouse in general. Numbers confirm that warehouse automation is becoming a necessity and an essential tool to grow a business in this market. Reports suggest that the warehouse automation market will grow from $15 billion in 2021 to $17 billion by the end of 2022. There are indications that by 2026, this market will expand to up to $31 billion.

How industrial mobile robots and reliable AGV networks are transforming automated warehouses

For years, the warehouse industry has been struggling to find a way to automate its operations in a way that is both efficient and cost-effective. But recent advancements in AGV technology have made it possible for warehouses to finally achieve the level of automation they need to stay competitive. AGVs have become a preferred solution for many businesses.

AGV benefits

One of the biggest benefits of AGVs is that they are highly versatile and can be used for a variety of tasks, from picking and sorting orders to transporting goods around the warehouse. This flexibility means that AGVs can be easily integrated into existing warehouse operations with minimal disruption. Additionally, AGVs are much more affordable than traditional industrial robots, making them a more viable option for small and medium-sized businesses.

Current problems in connectivity solutions for automated warehouses

So far, traditional Wifi has been a go-to connectivity solution from your couch to an automated warehouse. It’s hard to expect that an enterprise Wifi, designed for web browsing and video calls can work as successfully for mobile robots. Mobile robots’ light, latency-critical traffic and ever-changing Wifi signals do not have the same requirements as the bulky, relatively stationary traffic of laptops and phones.

Base stations, for example, work well with mobile phones. What happens with moving devices such as AGVs is that they face momentary disconnection whenever the signal is handed over from one base station to the next. This basically creates lags and wasted time.

A similar issue that makes AGVs temporarily lose connection is radio shadows. Whenever a link between the base station and the device is disturbed, the device loses connection. This means that whenever there is some kind of obstacle between the base station and the robot (for example, another robot), the connection is lost.

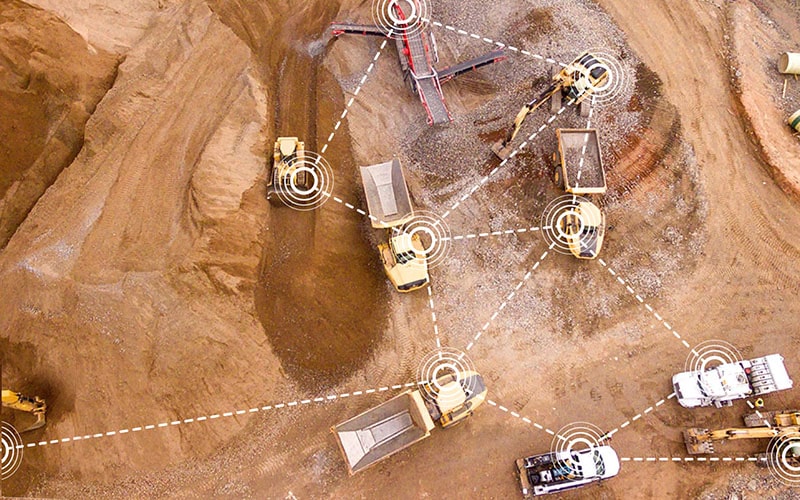

Meshmerize provides a solution to this problem. By using the Wifi infrastructure, Meshmerize can build a low-latency, highly reliable AGV network with a simple software update. No base stations, no clients, just nodes. Wireless mesh network nodes. This way, the robot itself becomes a part of the AGV network structure. Here you can find more information on how Meshmerize works.

Wireless mesh AGV network

Imagine you are the CEO of a large company and you need to cut costs. You have been told by your head of operations that one way to do this is by automating the manufacturing process with industrial mobile robots. But there is a catch—the factory floor is fairly large, and there are many potential obstacles that could get in the way of a successful automation deployment, such as forklifts or other vehicles moving around the floor. What is the best way to ensure uninterrupted communication between the robots so they can continue to do their job? The answer is a mesh network.

At its most basic, a mesh network is a type of network topology in which each node – in this case, each robot – is interconnected with every other node in the network. This allows signals to be dynamically routed around obstacles or areas of high interference, which is perfect for an industrial environment where there are often many potential obstacles that could interfere with network signals.

When deploying industrial mobile robots in a factory environment, it is important to have uninterrupted communication between the robots so they can continue working most efficiently. A wireless mesh network offers several benefits that make it ideal for this type of application, including:

-

Reduced infrastructure costs

Since mesh nodes can act as repeaters, you don’t need to deploy as many access points as you would with a traditional Wifi network. Each node, besides carrying a package, serves as a router itself. This can lead to significant infrastructure cost savings.

-

Increased coverage and AGV network reliability

Wireless mesh networks are designed to be highly reliable and offer increased coverage compared to traditional Wifi networks. Meshmerize mesh network software, for instance, offers a supreme solution to increased reliability.

-

Seamless roaming

Wireless mesh networks offer a real solution to the roaming problem that mobile robots often face. With mesh networks, there is no concept of changing access points – the robots just stay connected to each other, always.

-

Easy AGV network expansion

Wireless mesh networks can be easily scaled up or down as needed without incurring significant costs. Adding new nodes to a wireless mesh network is straightforward and can be done without disrupting existing communications. With mesh networking, infrastructure can be expanded truly wirelessly, without expensive cabling.

For example, Meshmerize can be incorporated into the existing Wifi, 4G, or 5G network trouble-free. This way, the AGV network can be extended deep into the warehouse structures without additional cabling.

-

Flexibility

Wireless mesh networks offer great flexibility. In other words, deployment—nodes can be easily moved or added as needed without having to reconfigure the entire network.

-

Robustness

Thanks to their decentralized nature, wireless mesh networks are intrinsically more resistant to failure than traditional Wifi networks.

-

AGV network Security

Since data is encrypted end-to-end in a wireless mesh network, it is more secure than traditional Wifi networks. Encryption makes it rather hard for someone outside the network to penetrate it and obtain information about it.

-

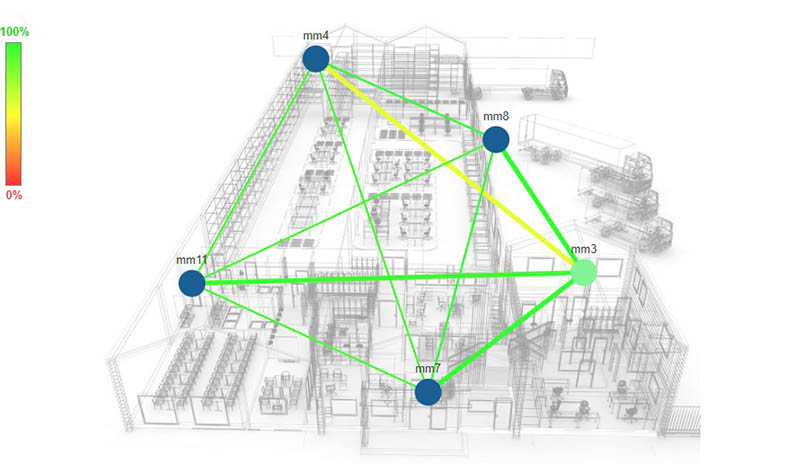

Visibility and control

Since all the robots and the AGV network infrastructure are part of a single network, it is possible to visualize the entire fleet and control the entire fleet from a single point. It is also possible for robots to collaborate even when the central service is down. Meshmerize even provides its own awesome UI for visualizing and managing the network nodes.

The future of an automated warehouse

As the cost of AGVs continues to decrease and their capabilities continue to increase, we will likely see even more warehouses adopt this technology in the coming years. Additionally, as AGV technology continues to evolve, we will likely see even more innovative applications for these robots emerge. For now, though, it’s clear that AGVs are playing a major role in transforming warehouse automation and making it more accessible than ever before.

Automated warehouse and AGV network superpowers

A wireless mesh network used in industrial applications offers reduced infrastructure costs, increased coverage and reliability, easy expansion, scalability, visibility, and flexibility. Additionally, wireless mesh networks are more resistant to failure than traditional Wifi networks. They also offer increased security thanks to their end-to-end encryption.

Can a wireless mesh network give automated warehouses new superpowers? Yes, indeed it can. When considering automating a manufacturing process with industrial mobile robots, it is advised to explore wireless mesh networks and their use potential first. It can result in a boost in robot productivity and a concurrent profit increase.

Meshmerize is a startup based in Dresden, Germany that provides the ultimate mesh network software to an array of industries. The full potential of Meshmerize is yet to be seen. We would like to hear your thoughts – let us know what you think at hello@meshmerize.net