Meshmerize’s latest deployment showcases the power of our innovative mesh networking solution. We have partnered with Movu, a member of the Stow Group family, to ensure a seamless warehouse network for their Atlas shuttles in one of the world’s largest autonomous warehouses.

This is one of the largest densely populated dynamic mesh networks in the world, demonstrating our unique ability to provide reliable and agile connectivity solutions for time-critical applications.

This deployment is a testament to our commitment to revolutionizing the future of Industry 4.0 robotics and logistics, and we can’t wait to share the details with you!

The article highlights Meshmerize’s innovative mesh networking solution, which provides reliable connectivity for high-performance shuttles in a large autonomous warehouse. Besides, it covers the challenges of managing the wireless network for time-critical applications, and how Meshmerize overcomes them through its unique multipath routing mechanism.

Warehouse network by Meshmerize revolutionizing logistics

Getting to Know Movu Atlas Shuttles

Atlas is a robust and efficient shuttle designed to perform in extreme conditions. With a temperature resilience ranging from a chilling -25°C to a sweltering +45°C and an impressive load capacity of up to 1,500 kg, it stands out as a powerhouse in warehouse logistics. Atlas’s deep lane access design is a game-changer for spaces where every inch counts. It allows optimal storage efficiency by reducing the need for wider driving aisles. And with a top speed of 1.4 m/s, it ensures that operations remain swift and efficient.

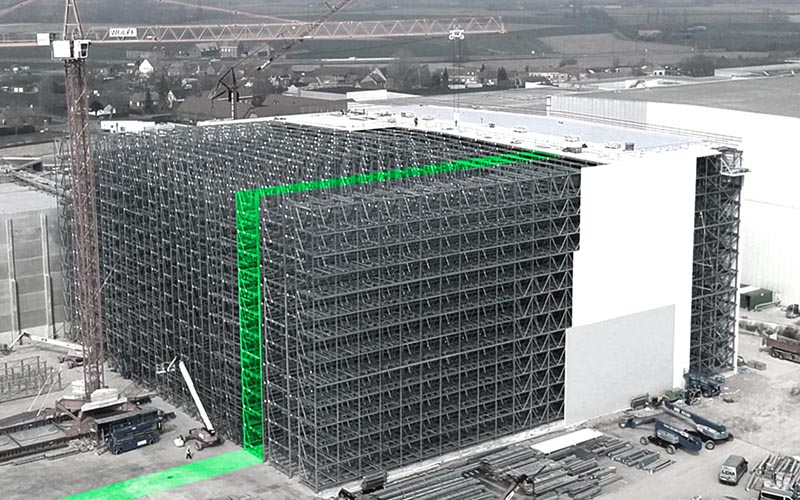

Exploring the Warehouse Network Scale and Setup

This 50m tall warehouse has 15 levels of storage of pallets and will be able to move 12.000 pallets in a time frame of 24 hours. It’s capable of storing over 80.000 pallets, each weighing up to 1 ton. From floor to ceiling, the racks and the entire structure are made of metal.

From a robotics standpoint, the site is fully automated with only minimal staff present on site. In fact, the site is so human-free that it is completely dark inside the warehouse – by design! It has 32 shuttles moving across the 15 levels. Central traffic controller system controls the shuttles.

The warehouse has a total of 66 strategically placed wireless access points that are connected by ethernet cables. We call these static nodes. The static nodes are Doodle Labs RM-2450 devices equipped with Omnidirectional (3 dBi) external antennas and are set up on an average of 20 m apart from each other, across three distinct floors of the warehouse.

The shuttles are the vehicles that move the pallets in and out of the racks. They are also fitted with the Doodle Labs RM-2450 devices running Meshmerize fitted with special antennas. They wirelessly transceive signals to/from the control device that operates the shuttle. The shuttles are capable of traveling at speeds of up to 4m/s, with an average speed of ~2 m/s.

Message prioritization for Safety and Traffic Control

First of all, there are both latency-critical and non-critical applications that depend on the wireless network. Meshmerize utilizes the dual radio setup to handle all the latency-critical applications with higher priority compared to the non-critical traffic. The static APs serve two separate wireless networks – one on the 2,4 GHz frequency and another on 5GHz. These two networks keep the mobile shuttles wirelessly connected for all their operations including low and high criticality applications.

To be specific, the central shuttle controller sends out MQTT traffic through the mesh to each shuttle once every 100ms. Every shuttle responds to these keep-alive messages on MQTT, updating the traffic controller of its position and state. A shuttle would be considered offline and go into a state of “disconnect” if it does not respond to a keep-alive message within 2 seconds of the controller sending it. Yes, that’s a round trip, application-application time!

Challenges in maintaining connectivity

This might seem like a big enough window for non-mobile or slow-moving devices in a warehouse network. But, this is a particularly challenging scenario for modern dense intralogistics robots. During their regular operations, the shuttles travel back and forth across the warehouse, possibly carrying liquids, crossing a static access point every ~10 seconds. Given the context of roaming shuttles with metallic racks all around them and obstacles on top of them, keeping the shuttles connected all the time is a humongous task.

Along with the keep-alive packets, the wireless network also needs to carry all the necessary control traffic as well, making it its sole responsibility to keep the warehouse running smoothly.

The bandwidth used by raw MQTT data is around 50 kbps. Considering the actual data size alone is not indicative of the traffic. The rate at which these messages are sent and the number of nodes makes this number quickly add up. In reality, adding the network headers and other overheads, the throughput of the network is in the range of 200-250 kbps.

Meshmerize: Low Latency, Zero Handover Times in a Warehouse Network

The bandwidth may not seem like much. But the environment and high-speed mobility are what make this task extremely challenging for wireless networking. Actually, conventional WiFi, with roaming capabilities, has expected handover times between access points of 50ms. In practice, this time is usually 100ms – 500ms with occurrences of delays of up to 2 seconds. As a result, it’s highly likely that each shuttle would experience multiple disconnections per minute. This is capable of bringing the entire warehouse to a complete halt.

With about 100 nodes and thousands of links between them, Meshmerize efficiently manages packet routing through its multipath routing mechanism. This allows for seamless roaming for all 32 shuttles in the warehouse. They maintain multiple connections while on the move around the warehouse, with zero handover times. The average ping times of the safety network is around 10ms with very low jitter.

Managing Other Traffic Types in the Warehouse Network

Although the control and safety traffic in the warehouse network is latency-critical and must be transmitted quickly, there is other traffic that is equally important for seamless warehouse operations. This includes traffic related to logging and remote access capabilities. This type of traffic doesn’t require the same level of reliability as control and safety traffic. On the other hand, it still needs a high-bandwidth to the shuttles. This route, which may have larger handover times and lower reliability, is used by logging servers and site engineers for vital operations and maintenance tasks.

Additionally, each of the shuttles also hosts a “hotspot” that maintenance personnel can manually connect to in order to drive the shuttle around using their smartphones during an intervention.

Meshmerize simplifies the process of managing warehouse network traffic by bringing together all of these requirements into one comprehensive solution. With Meshmerize, site staff can easily set up new nodes without the need for any manual configuration. All that’s required is providing each device with a unique name, which is then used by the traffic controller server to keep track of them.

Transforming Connectivity with Mesh Warehouse Network in Collaboration with Movu

Having the warehouse in full-scale production since spring 2023 has been a monumental achievement, made all the more significant by our partnership with Movu. Collaborating with such an innovative partner has been a gratifying journey. Their Atlas shuttles, a testament to state-of-the-art logistics technology, combined with Meshmerize’s networking features, exemplify the future of Industry 4.0. If you want to learn more technical information about this project, you can check this case study.

At Meshmerize, we believe that mesh networking holds immense potential to reshape connectivity across various industries. Our experience with one of the world’s most densely populated autonomous warehouses stands as evidence of our capability to handle challenges with grace and efficiency.

It’s partnerships like the one we have with Movu that inspire us to keep pushing boundaries. As we move forward, our focus remains on enabling organizations to harness their full potential, breaking barriers, and unlocking new horizons.

We’re excited to explore new opportunities and help organizations unlock their full potential with the power of Meshmerize. With our advanced mesh technology, we’re breaking barriers and creating new possibilities for businesses of all kinds.

If you’re ready to experience the transformative power of Meshmerize for yourself, we encourage you to reach out to us today and unlock the full potential of your devices.

Meshmerize is a startup based in Dresden, Germany that provides the ultimate mesh network software to an array of industries. The full potential of Meshmerize is yet to be seen. We would like to hear your thoughts – let us know what you think at [email protected]