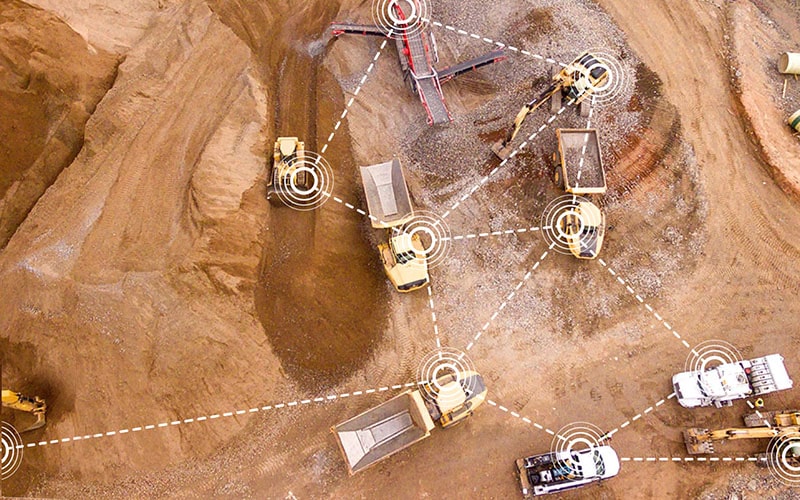

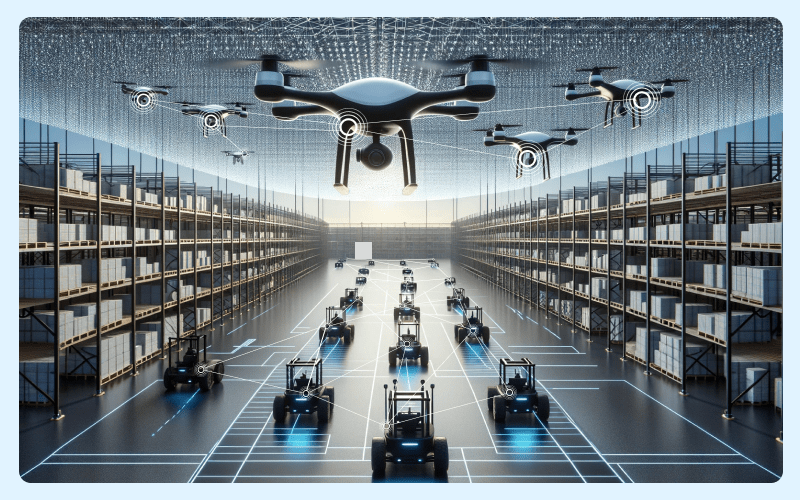

Automated warehouses face connectivity challenges that impact the performance of the AGVs and AMRs. These challenges include AGV connectivity loss, sudden failures, delays, and rigid infrastructure requirements. Mesh Wifi for warehouse offers several advantages over traditional networking solutions, making them ideal for warehouse environments. The mesh network allows robots to communicate with each other and with the network, creating a reliable, flexible and cost-effective infrastructure. Warehouse managers can improve their operations’ performance, productivity, and safety, making the warehouses run like well-oiled machines.

In this blog, we’ll be discussing the game-changing technology that’s affecting the way automated storages are running and being managed.

Solving Warehouse Connectivity Challenges with Mesh WiFi for Warehouse

1. Seamless roaming

Issue: Staying connected on the move

In a conventional network setup, devices are organized into multiple hub-and-spoke systems with access points serving as hubs, and devices such as robots and laptops serving as spokes.

The drawback is that, as robots move from one location to another, they must disconnect from one access point and connect to another, which can take anywhere from a few hundred milliseconds to several seconds. This time offline can have significant impacts on the efficiency and safety of operations.

In Industrial settings, the safety triggers for a wireless system are typically set-off when a device is not responsive for more than 500ms – 2000ms. The disadvantage of the hub-and-spoke model really starts showing here as when they start roaming and switching between access points, not only does one node get disconnected, it has the potential to send the entire system to a safety shutdown.

And when dozens of shuttles are doing this, warehouses experience multiple interruptions per hour!

What makes it worse is that lost nodes sometimes have to be manually attended to. AGV connectivity issues while roaming cause cumulative productivity losses of hundreds of robot-minutes every day.

Solution:

Mesh networks provide a solution to this problem by ensuring that AGVs and AMRs stay connected at all times. With Meshmerize, devices can communicate not only with the access points but also with each other, which allows for seamless transitions as they roam.

Robots can constantly hear each other and assist each other, allowing for new connections to be established before old ones are lost. This effectively eliminates roaming handover times, ensuring that operations continue smoothly and robots roam seamlessly.

2. Undisturbed by radio shadows

Issue: Connection obstructing shadows

Metallic structures, walls, and other obstacles, combined with the constant flow of robots and goods inevitably lead to the creation of radio shadows. As we know, metals tend to form what is known as a Faraday Cage, posing an immense challenge to AGV connectivity.

From a standpoint of a traditional hub-and-spoke model wireless network, this means that there would be “dark zones” or “radio shadows” – areas where the AP just isn’t able to send out strong signals. Not just that, in a warehouse that is constantly seeing material movement, these dark zones keep shifting and changing, making it impossible to fully plan for.

Then why not flood the place with wireless signals? If we do that, then the problem of roaming kicks in, as the robots constantly keep switching between Access Points.

Additionally, there is the problem of overuse of the medium, causing bandwidth degradation and packet losses. This tricky challenge stands in the way of maintaining wireless AGV connectivity and leads to major problems in automated warehouses.

Solution:

Meshmerize helps alleviate the negative impact of dynamic dark zones, without even eliminating them. How so? Messages are relayed through multiple nodes, keeping devices interconnected even in the toughest conditions. As long as nodes can detect just one other node, the network operates seamlessly. This smart and cooperative approach ensures a smooth experience, regardless of obstacles. We don’t have to plan to eliminate dark zones, we just have to cooperatively overcome their ill effects.

3. Prioritized traffic

Issue: Too much noise, not enough signal

When the same network is used to relay both control messages and other, less important data such as images, it can easily lead to congestion and critical data getting lost in the shuffle. Data such as images or videos take much more bandwidth, making less room for important data to move quickly.

In an automated warehouse it is imperative that we separate the traffic into two buckets – primary traffic would contain only movement and safety related messages, secondary traffic would contain logging, imagery and other important but non safety critical data. With conventional WiFi networks, this has to be achieved through multi-tiered infrastructure, making it expensive and complicated.

Solution:

Meshmerize allows you to prioritize the traffic in your wireless network for greater safety and reliability by allowing you to use a single network infrastructure for multiple types of data with different priorities.

Typically, we implement Meshmerize in a way that we create rules that route the traffic either through the highly robust mesh network or through a higher bandwidth, but less robust auxiliary network. Even within the mesh, packets can be assigned priority orders, to ensure higher quality of service for more important data-packets such as safety signals.

Our multipath routing algorithm secures prioritized status for important messages through multiple redundant paths.

4. Scalability

Issue: Growing Pains

At smaller scales, traditional wireless networks work pretty well for warehouse management robots. The issues with the wireless networks typically start showing up as the number of nodes increase and the area of the warehouse increases.

With a larger number of active nodes, networks tend to get overwhelmed, causing outages and disconnects. Also, problems such as roaming and radio-shadows become more evident and much more troublesome at scale.

Solution:

Meshmerize’s smart routing algorithm ensures high scalability and reliability, allowing hundreds of devices to join a single network. This makes it ideal for use in large-scale warehouses.

Meshmerize is designed to be highly dynamic and adaptive, constantly working for a good trade-off between high-reliability and high-bandwidth. While keeping reliability high, Meshmerize constantly keeps trying to increase data rates to the limit to which the environment would safely allow. This ensures that you can add hundreds of nodes to the mesh network without experiencing issues like disconnects due to roaming or radio shadows.

Hive – the dynamic overview

Managing a network of AGVs or AMRs can be quite a task. This is why we created Hive, our very own network management system.

With Hive, you can constantly have an overview of the whole network, both static and dynamic devices. Other management operations such as configuring, analyzing, and upgrading the mesh network are a breeze.

Not only will you be able to keep an eye on your network’s performance, but you’ll also be able to make any necessary changes to keep it running smoothly. And in the rare case that something does go wrong, you’ll have all the tools you need to quickly identify and fix the issue.

Hive also provides APIs that enable seamless communication between your warehouse management system and Hive. This means that information about your network and robots can be effortlessly exchanged, providing you with even greater visibility and control.

Out-of-the-box mesh WiFi for warehouse solution

Having to navigate through inappropriate network devices with engineering hacks can make setting up a network in an automated warehouse a living nightmare.

Meshmerize is an out-of-the-box wireless network software solution for mesh WiFi for warehouse, AGVs and AMRs. With straightforward reliable network setup and management, it’s especially convenient for intralogistics facilities.

How can you get it? Easy.

Getting Meshmerize

You may be eligible to try Meshmerize for FREE!

If you’re interested to see if your are eligible for a free trial, don’t hesitate to contact us at [email protected]

Outcomes

Meshmerize revolutionizes the way warehouses operate by boosting AGV connectivity and coordination with mesh WiFi for warehouse. Some of the proven Meshmerize results include 100% coverage, overall efficiency and productivity improvement, and downtime decrease.

Meshmerize is a game-changer in the world of wireless network solutions for warehouses. It is a feature-rich solution that effortlessly solves the typical network issues found in automated warehouses. It also goes above and beyond by providing even more value.

You move, we connect.

Let the robots roam free.

Meshmerize is a startup based in Dresden, Germany that provides the ultimate mesh network software to an array of industries. The potential of Meshmerize is yet to be seen. We would like to hear your thoughts – let us know what you think at [email protected]